Laser Marking on Silicones

Marking on silicone elastomers can be challenging. Extremely. But thanks to laser marking, even the most challenging of polymers – such as silicone cables or medical tubing – can be marked accurately and easily.

COLLABORATION WITH WACKER

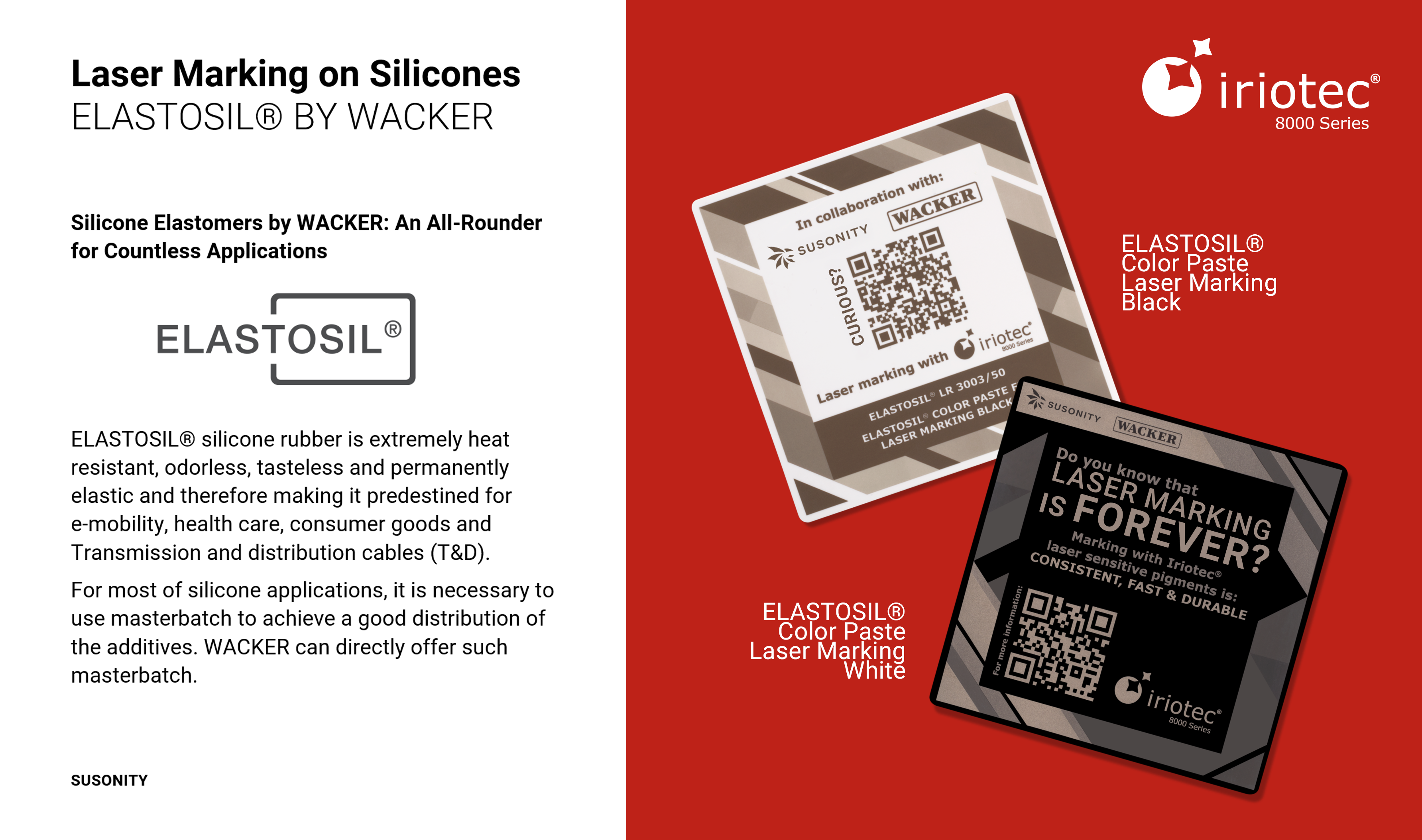

In collaboration with our partner, Wacker Chemie AG – a market leader in silicone materials – we have created permanent and durable laser marking on silicone with our Iriotec® 8000 series. The target applications are typically found in the cable and tubing industry.

- Achieve consistent, fast, and durable marking on silicone surfaces with the Iriotec® 8000 series

- Produce accurate line definition and contrast

- Ready-to-use masterbatches for black and white markings are available from WACKER

SILICONE ELASTOMER

Silicone rubber essentially consists of silicone polymers and fillers. The polymers are cross-linked with suitable reactants to produce three-dimensional structures that convert the fluid or ductile rubber compound into an elastomer. Thanks to their thermal and chemical resistance and inert nature, silicone elastomers are suitable for a wide range of applications, such as medical tubes, cables, and consumer products like baking molds, sports items, and leisure articles. For example, silicone cables are used as heat-stable cables or as flame-retardant safety cables in electric vehicles, but also in places like airports and official constructions.

Placing a permanent marking on products is an ever-increasing market demand – which has until now been a challenging task for silicone elastomers. Our laser-sensitive pigments Iriotec® 8000 series are changing this and are available as ready-to-use masterbatches from WACKER for liquid (LSR) and solid silicone rubbers (HTV).

TDS SILICONE MASTERBATCH

WACKER offers ready-to-use masterbatches for laser marking of silicones in black and white. Check out the TDS of ELASTOSIL® Color Paste:

For liquid silicone rubber (LSR):

For solid silicone rubber (HTV):

Surface Solutions

We are the experts who make the world more beautiful!

Information on hazard classes or hazard categories can be found in the safety data sheet.

© 2025 Merck KGaA, Darmstadt, Germany and/or its affiliates. All Rights Reserved.

Reproduction of any materials from the site is strictly forbidden without permission.